What Is A 3D Printed Robotic Arm?

Most robotic companies use 3D printing technology in the development of their robots to provide extra benefits of 3d printed robotic arm It is a smart step to achieve more recognition in the robotic industry. This technique will help manufacturers to achieve more popularity and encouragement to produce more Robot 3D Printer.

What is robotic 3D printing?

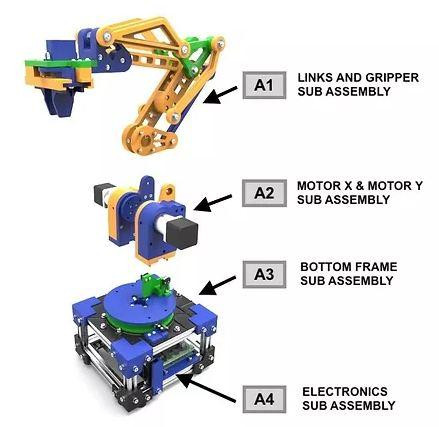

Robotic 3D printing can have multiple meanings in different contexts. Mostly, it refers to a 3D printing robotic arm which can be used to refer to RAM. RAM is a technology used in 3D printing. When a pinhead is mounted to a robotic arm it provides additional degrees of mobility freedom. With this technique, powerful robots you can build.

What is the use of robotic 3D printing?

Engineers prefer to use this technology to achieve the flexibility of customization. They use both technologies; 3D printing and robotics and additive manufacturing to achieve better results while designing more efficient robots. Lastly, it will allow having Robot 6 Axis to reduce the stress of workload.

With 3D printing, companies can produce robots with advanced technology. According to the experts, 3D printing enhances the technology of the robots resulting in better productivity in their work. Moreover, this technique lets engineers achieve their goals of creating advanced robots for customers and users.

What are the advantages of 3D printing technology?

There are various advantages of robotic arms for 3D printing.

Size:

Most Robot 3D Printers help sustain large scale robotic 3D printing. The reason is that most robotic arms can transcend the build area of a regular 3D printer. According to the experts, robots can 3D print stakes up to thirty metres in size.

Design freedom:

Multi-axis 3D printing allows robots to have geometrical freedom. For instance, a 3D printing robot arm can print a curve. Multi-pivot 3D printing gives mathematical opportunities. A 3D printing robot arm can, for instance, print a bend (non-planar 3D printing), while a conventional 3-pivot FDM 3D printer can surmise one: layers are frequently noticeable, delivering a ventured result.

Support-free

Mechanical 3D printing can eliminate reliance on help structures in more ways than one. One way includes a moving print bed: shifting the print bed can transform flat distension into an upward one that doesn't require supporting.

A further developed arrangement is to utilise complex freestyle 3D printing strategies. The Mediated Matter Group at MIT has utilised mechanical arm 3D printing to print sans support structures such that imitates a silkworm turning its cover.

Composite printing:

Automated added substance assembling can work on composite printing.

US-based organization Continuous Composites has likewise investigated persistent fiber support with their noteworthy CF3D innovation.

Summing up:

For advanced mechanics plans, 3D printing is great for fast prototyping. Planning advanced mechanics requires a great deal of experimentation. This starts with an idea and different plan boundaries that are utilized to meet a planned application or schedule. Models might be grown rapidly, economically, and with little in general gamble, through a 3D printing process. You can order DIY robotic kits with the info on How to build robots.

Comments

Post a Comment